Insights Assetbank

Digitalisation in Manufacturing SMEs

Contributor: Eleanor Precious, WMG SME group

The WMG Approach

The WMG SME group helps the manufacturing supply chain embed digital technology into their day-to-day activity via tailored projects, internships, and low-cost technical solutions. SMEs need to ensure that they are implementing the right technology into their business, as it is easy to get bombarded with all the solutions out there.

Before recommending a particular technology or solution, our approach is to work with manufacturers to understand their unique issues and priorities. We look at the current state of a factory and what the future state needs look like. We look at how data is currently used and through observing the production process in-depth including cycle times, equipment use and downtime, levels of work in progress and inventory, we identify opportunities for growth and increased profitability alongside a digital road map outlining where digital technology can help.

We are supporting manufacturing SMEs with the implementation of digital in a range of scenarios.

Business Continuation (Case 1 Alphateq Ltd)

It is widely known that introducing digital manufacturing into a business will help drive productivity gains, but perhaps more crucially it contributes to the survival of smaller more traditional firms, allowing them to compete on a global scale.

One such business is Alphateq, a Warwickshire based patternmaking firm. Managing director Brian Garforth recognised that digital technology was going to play an ever more meaningful role in the future development of the company. They were largely paper based and struggling with visibility of what was happening on the shop floor. They were unaware of how long jobs were taking and what resource was being used to accurately quote for new work. Through our internship programme. Shantnu Mehta, a graduate from the University of Warwick joined the firm to help them get an ERP system set up which has allowed managers to track the jobs more efficiently, automatically assign new jobs to the operator, machine, and station and gather all the important analytical data which enables them to understand their profitability and quote accurately for new jobs in the future. With better costing data now, Alphateq aims to increase their client conversation rate by 10% this year which could result in additional turnover of £250,000.

De-risking new expansion projects (Case 2 Jaltek Systems Ltd)

Another way to use digital is to visualise and plan for new factory layout and expansions. Jaltek Systems, a contract electronics manufacturer based in Luton were experiencing growing demand for a particular product and they approached WMG to help with their plans to set up a new facility to realise their ambitious growth targets.

After analysing Jaltek’s “current state” of production, we conducted a laser scan of the current facility production areas and the new facility production area. This enabled a series of recommendations for improvements and the design of an optimal digital 3D version of the “future state” for the new facility that could be customised going forward. The new design using digital technology offered a potential 75% increase in capacity which allowed Jaltek to meet the surges in demand and helped de-risk the move into the new factory and onboard two major new clients worth over £2 million to the business.

Automating Processes (Cases 3 & 4 JCM Fine Joinery Ltd and Billingham Bags Ltd)

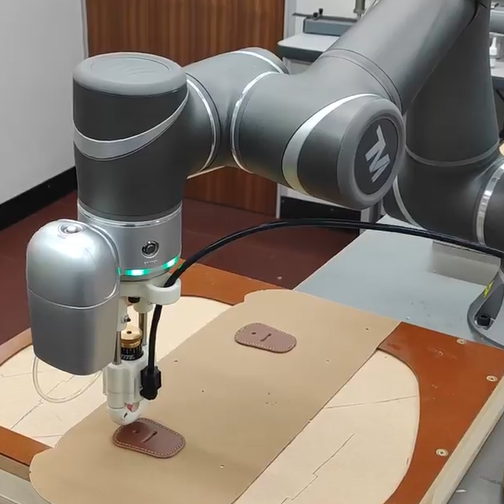

Introducing some level of automation is often the first step SMEs take when introducing digital technology and collaborative robots (cobots) require less financial investment.

JCM Fine Joinery, a commercial joinery company based in Halesowen worked with us through the Made Smarter West Midlands scheme to embed a robot to carry out the sanding process in the business. It is already exceeding its targets, saving time, and creating efficiencies.

And Billingham Bags worked us to understand the advanced capabilities and limitations of a cobot they had bought. A WMG intern helped this firm generate a control code for the specific task of dispensing and applying superglue adhesive and made use of the robot’s built-in vision system to locate workpieces and detect stitched patterns automatically. He was also able to modify the robot’s behaviour to improve performance for complex stitching patterns and workpieces.

Business Growth (Case 5 Ludlow Nut Company)

A business will get to a point where it just cannot manage its systems on an ad hoc basis. This was the case with the Ludlow Nut Company in Shropshire, a small artisan producer of healthy food that was seeing big increases in demand for its own products as well as its white labelling service for other brands.

Helen Graham who co-founded the business in 2014 said: “I think we had got to the stage where we had become too big to maintain our efficiency through our previous system and that was the key for us. The worst thing is when you are about to start making a product and you realise you don’t have a particular ingredient because that causes lost time and re-shuffling other orders.”

Denis Pelych of WMG worked with Ludlow to get the go ahead for a grant towards a Material Requirements Planning (MRP) software-based system. Their new system allows them to track stock from the goods-in stage through to recipe production, packaging, and finally dispatch to customers.

As a result, Ludlow noted:

- 30% reduction in time to process orders and plans

- 10-20% reduction in management time compiling reports (re-focused on strategy)

- 10-20% reduction in non-value-added admin, expediting & error correction

- 15-20% productivity improvement from shop floor data capture

- 5-10% reduction in downstream manufacturing waste (fewer errors)

This amounts to total savings of 125k pa and equates to extra capacity to improve their bottom line.

Dr Mark Swift, Director of SME Engagement at WMG says.

“When it comes to digitalisation in manufacturing SMEs, our approach is to cut through the tech jargon and get things done. We operate a “technology plus” model meaning we introduce SMEs to new technology and new operating models but focus on ensuring the new approaches stick by spending time understanding their individual processes, current markets, and customers. That way solutions are tailored to them and will have a positive return on investment.”

WMG, University of Warwick has a range of funded programmes to help manufacturers with digitalisation as well as with decarbonising and becoming more energy efficient. Contact wmgsme@warwick.ac.uk for more information.

Article first published in The Manufacturer: https://www.themanufacturer.com/magazine/the-manufacturer-november-december-2023/